Supply chain bottlenecks have proven to be a significant challenge for brands and retailers in recent years. The Ever Given’s grounding in the Suez Canal in 2021 brought the global supply chain to a standstill, demonstrating the fragility of interconnected supply chains and the devastating impact of even minor disruptions. This incident served as a stark reminder of the importance of resilience and agility in e-commerce supply chains. Businesses that can adapt to unforeseen events and maintain a smooth flow of goods are the ones that will thrive in the face of future supply chain disruptions.

In light of these global events and the complexities of modern supply chains, it is crucial for businesses to take a proactive approach to managing supply chain bottlenecks. By understanding the root causes of these disruptions, implementing preventive measures, and embracing innovative technologies, brands can build resilient and agile supply chains that are capable of navigating challenges and delivering exceptional customer experiences.

What is a Supply Chain Bottleneck?

Imagine a well-oiled machine, each component seamlessly working together to produce a smooth, efficient process. Now, picture a tiny pebble stuck in the gears, causing the machine to grind to a halt. That pebble is akin to a supply chain bottleneck, a disruption that hinders the flow of goods and information within a supply chain.

Supply chain bottlenecks can manifest in various forms, from port congestion and labor shortages to transportation delays and inventory imbalances. These supply chain issues can have a ripple effect, causing stockouts, a delay in deliveries, and frustrated customers.

The 2021 Suez Canal blockage, caused by the grounding of a massive cargo ship, serves as a stark reminder of the fragility of global supply chains. This incident caused massive delays and disruptions, impacting the movement of goods and driving up shipping costs.

The COVID-19 pandemic has also highlighted the interconnectedness and vulnerability of supply chains. Lockdowns, factory closures, and labor shortages have created bottlenecks at various stages of the supply chain, leading to product supply shortages, price increases, and longer delivery times.

The Impact of Bottlenecks on Businesses

Supply chain bottlenecks are not mere inconveniences; they can have a profound and lasting impact on businesses of all sizes. The ripple effects of these disruptions can be felt throughout an organization, affecting finances, customer satisfaction, and long-term growth prospects.

Increased Costs and Financial Implications

One of the most immediate consequences of supply chain bottlenecks is a surge in operational costs. As businesses grapple with disruptions, they may face higher transportation costs, increased labor expenses, and challenges in inventory management. These added expenses can erode profit margins and constrain financial resources.

In some cases, businesses may be forced to pass on these increased costs to consumers in the form of higher prices. While price hikes may help businesses recoup some of their losses, they can also strain customer relationships and dampen demand.

Delivery Delays and Customer Dissatisfaction

Supply chain bottlenecks often lead to delays in order fulfillment, leaving customers waiting for products they have already paid for. These delays can cause frustration, erode trust, and damage brand reputation.

Delays can also disrupt businesses’ carefully crafted marketing campaigns and promotional efforts. If customers cannot receive products within the expected timeframe, the excitement and anticipation generated by marketing initiatives can quickly turn into disappointment and frustration.

Lost Revenue and Growth Opportunities

Recurring supply chain bottlenecks can hinder a company’s ability to meet consumer demand and capitalize on market opportunities. When products are unavailable or delivery times are unpredictable, businesses risk losing sales to competitors who can provide a more consistent and reliable service.

Moreover, supply chain disruptions can derail a company’s growth trajectory. If businesses cannot effectively manage their supply chains, they may struggle to expand into new markets, launch new products, or respond to changing consumer demands.

Common Causes of Supply Chain Bottlenecks

Supply chain bottlenecks are not isolated incidents; they often stem from a complex interplay of external factors and internal challenges. Understanding the root causes of these disruptions is crucial for businesses to develop effective mitigation strategies and build a more resilient supply chain.

External Factors

The globalized nature of supply chains exposes businesses to external forces that can create significant disruptions. These factors, often beyond the direct control of businesses, can have a domino effect, causing bottlenecks to cascade throughout the supply chain.

Pandemics, political instability, and economic downturns can disrupt global supply chains, leading to shortages, production slowdowns, and transportation delays. Events such as hurricanes, earthquakes, and wildfires can damage infrastructure, disrupt transportation routes, and cause power outages, hindering the movement of goods and information. Trade disputes, political instability, and regional conflicts can create barriers to trade, restrict access to resources, and disrupt supply chain flows.

Internal Challenges

While external factors can trigger supply chain bottlenecks, internal challenges often play a significant role in exacerbating these disruptions. By addressing internal inefficiencies and adopting best practices, businesses can reduce their vulnerability to supply chain disruptions.

Ineffective inventory management practices, such as inaccurate forecasting, overstocking, and understocking, can lead to stockouts and excess inventory, creating bottlenecks and increasing costs. Lack of clear communication and collaboration between departments and partners can lead to delays, errors, and missed opportunities, hindering the smooth flow of goods and information. Insufficient production capacity can constrain supply and create bottlenecks, especially during periods of high demand. Investing in production capabilities and exploring alternative sourcing options can help mitigate these challenges. Inefficient transportation networks, congested ports, and limited transportation options can delay deliveries and increase costs, creating bottlenecks at various stages of the supply chain.

How to Prevent Supply Chain Bottlenecks

Supply chain bottlenecks are not inevitable roadblocks; they can be prevented or mitigated through proactive strategies and continuous improvement initiatives. By addressing the underlying causes of these disruptions, businesses can enhance their supply chain resilience, maintain operational efficiency, and ensure customer satisfaction.

Enhancing Inventory Management

Effective inventory management techniques are the cornerstone of supply chain resilience. By gaining real-time visibility into inventory levels across all locations and channels, businesses can make informed decisions about procurement, production, and distribution.

Accurate forecasting, based on historical sales data, market trends, and promotional activities, helps businesses anticipate demand and optimize inventory levels. This proactive approach prevents stockouts and overstocking, reducing the likelihood of bottlenecks and minimizing unnecessary costs.

Strengthening Communication Channels

Open and transparent communication is essential for preventing supply chain issues and disruptions. Businesses should foster strong supplier relationships, keeping them informed about demand changes, potential disruptions, and any modifications to production schedules.

Similarly, maintaining transparency with customers about potential delays or stockouts can help manage expectations and minimize customer frustration. Clear communication can also help identify potential problems early on, allowing for proactive solutions to be implemented.

Expanding Production Capacity

As consumer demand fluctuates, businesses need to be able to adapt their production capacity accordingly. Investing in technology, such as advanced manufacturing systems and automation, can enhance production efficiency and increase output.

Expanding production facilities and building new manufacturing plants can also help businesses meet growing demands and reduce their reliance on external suppliers, potentially mitigating the impact of supply chain disruptions.

Streamlining Transportation and Delivery Logistics

The final mile, the last stage of the supply chain, often presents a critical bottleneck. By streamlining transportation and delivery logistics, businesses can ensure timely and efficient deliveries, enhancing customer satisfaction and reducing delivery costs.

To ensure timely deliveries and minimize disruptions, brands should forge partnerships with reliable and efficient transportation providers. Additionally, they should adopt last-mile optimization strategies, employing route optimization software and delivery management systems to streamline delivery routes, reduce fuel consumption, and improve delivery times. Furthermore, leveraging technology such as real-time tracking, predictive analytics, and delivery automation can enhance visibility and control over the delivery process, fostering seamless and efficient deliveries that exceed customer expectations.

Embracing Technology and Innovation

By embracing innovative solutions, businesses can gain real-time visibility into their supply chains, automate repetitive tasks, and optimize decision-making processes.

The Role of AI in Supply Chain Management

Artificial intelligence (AI) has emerged as a transformative force in CPG supply chain management, revolutionizing the way businesses forecast demand, anticipate disruptions, and optimize decision-making processes. AI algorithms, fueled by vast troves of data, can analyze historical sales patterns, market trends, and external factors to generate highly accurate demand forecasts, enabling businesses to proactively adjust inventory levels, production schedules, and marketing strategies.

Moreover, AI’s predictive capabilities extend beyond demand forecasting, empowering businesses to identify potential supply chain bottlenecks before they arise. By analyzing data on inventory levels, transportation patterns, and supplier performance, the use of AI in supply chain management can help detect anomalies and predict potential disruptions, allowing businesses to take preemptive measures to mitigate risks and maintain a smooth flow of goods.

The Benefits of Integrated Management Systems

Integrated management systems (IMS) have emerged as the cornerstone of a modern, technology-driven supply chain. These comprehensive systems seamlessly integrate inventory, warehouse, and delivery management functionalities, providing businesses with a holistic view of their supply chain operations.

IMS empowers businesses to achieve unprecedented levels of efficiency and control. Real-time inventory visibility enables informed decisions about procurement, production, and distribution. Warehouse management systems optimize storage space, streamline picking and packing processes, and minimize order fulfillment times. Delivery management systems optimize delivery routes, track shipments in real-time, and provide automated notifications to customers.

Building a Resilient and Agile Supply Chain

Achieving resilience and agility necessitates a proactive approach to supply chain management, one that prioritizes contingency planning, embraces adaptability, and equips employees to navigate change effectively.

The Importance of Contingency Planning

Contingency planning is the bedrock of a resilient supply chain, providing businesses with a roadmap for navigating unforeseen challenges and minimizing the impact of disruptions. By identifying potential risks and developing proactive mitigation strategies, businesses can safeguard their operations and maintain a steady flow of goods to customers.

Effective contingency planning involves identifying potential disruptions, developing backup strategies, and regularly reviewing and updating plans.

Fostering Supply Chain Agility

In an ever-changing e-commerce landscape, agility is not just a desirable trait; it is a survival imperative. Businesses that can adapt to changing demands, pivot to new strategies, and quickly adjust their operations are the ones that stay ahead of the curve.

Fostering supply chain agility requires real-time visibility, data-driven decision-making, embracing technology, and empowering employees.

How Flowspace Can Help Navigate Supply Chain Bottlenecks

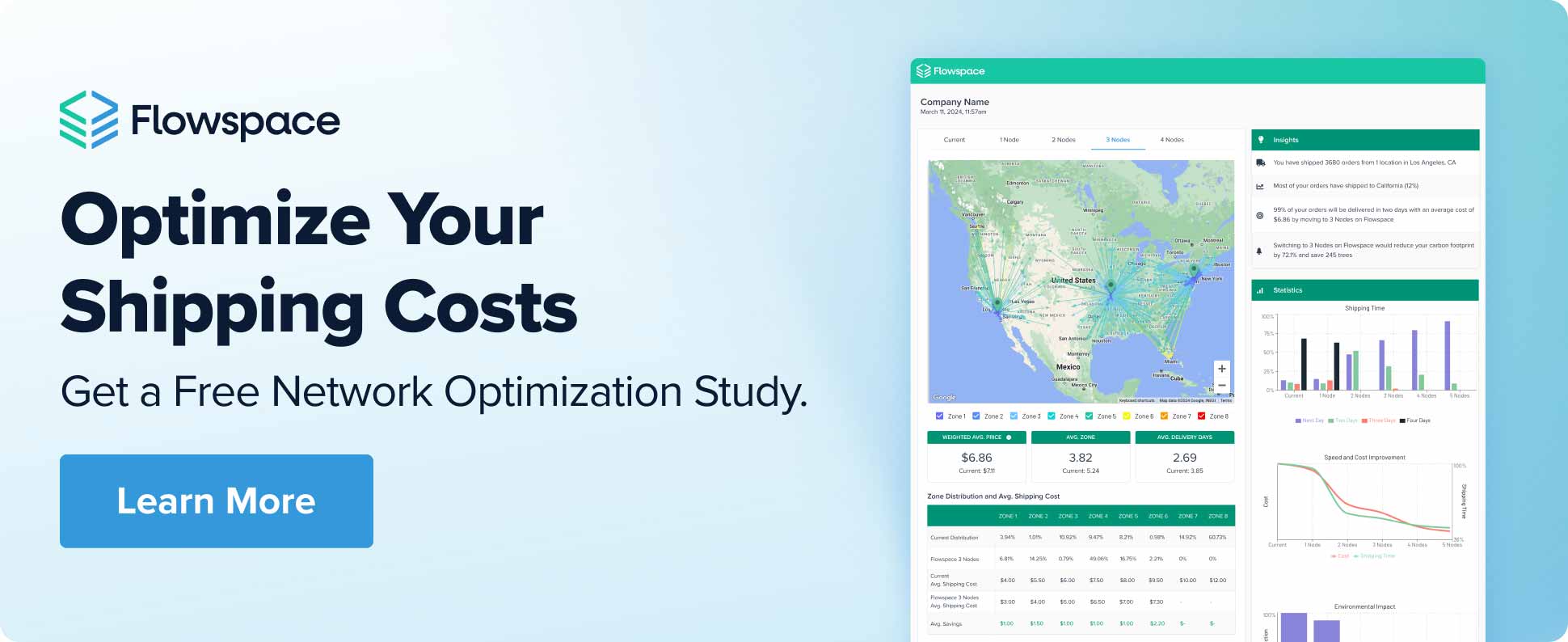

Flowspace, a leading provider of ecommerce fulfillment solutions, empowers businesses to overcome these supply chain bottlenecks and achieve supply chain agility with its comprehensive suite of services and innovative technology.

Flowspace’s Advanced Warehousing Solutions

Flowspace’s warehousing solutions are designed to prevent and mitigate supply chain bottlenecks. With on-demand capacity and a flexible, nationwide network of warehouses, Flowspace provides businesses with access to the right space, in the right location, to meet their unique supply chain needs.

Real-time Inventory Tracking with Flowspace

Real-time inventory visibility is crucial for preventing supply chain bottlenecks. Flowspace’s robust inventory management platform provides businesses with real-time visibility into inventory levels across all warehouses, enabling them to monitor inventory levels, set reorder points and analyze usage patterns.

Partnering with Flowspace for End-to-End Supply Chain Optimization

Flowspace’s expertise extends beyond warehousing to encompass a wide range of global supply chain optimization solutions. By partnering with Flowspace, businesses can gain access to a comprehensive suite of services that streamline operations, eliminate any potential bottlenecks, and enhance overall supply chain efficiency.

Get in touch today to see how Flowspace can supercharge your supply chain and remove supply chain bottlenecks.