Inventory management is a critical component of any business’s operations, and it can make or break a brand’s bottom line. Successful inventory management is all about avoiding waste while maximizing customer satisfaction and reducing costs.

Both industry giants and small brands rely on effective inventory management strategies to drive productivity and ensure profitability. In this article, we explore inventory management techniques that have proven instrumental in achieving operational excellence.

What is Inventory Management?

Inventory management encompasses the critical processes of tracking, ordering, maintaining, and optimizing the stock required for seamless business operations. Successful businesses recognize the importance of optimizing inventory management techniques tailored to their unique business model, priorities, and specific needs.

Types of Inventory Management Techniques to Know

FIFO vs. LIFO

First-in, first-out (FIFO) and last-in, first-out (LIFO) are two of the most common inventory management techniques. Both methods have their own advantages and disadvantages, and the best method for a business will depend on its specific needs and goals.

FIFO

FIFO inventory management assumes that the oldest items in inventory are sold first. This method is often used for perishable goods, such as food and pharmaceuticals, to ensure that customers receive the freshest products possible.

FIFO is also a good choice for businesses that want to minimize their overall inventory cost. This is because FIFO matches the cost of goods sold to the cost of older inventory, which is typically lower than the cost of newer inventory.

LIFO

LIFO inventory management assumes that the newest items in inventory are sold first. This method is often used by businesses that want to reduce their taxable income. This is because LIFO matches the cost of goods sold to the cost of newer inventory, which is typically higher than the cost of older inventory.

Which is a Better Choice?

When it comes to FIFO vs LIFO, LIFO can also be a good choice for businesses that sell products with prices that are rising over time. This is because LIFO allows businesses to delay recognizing the higher inventory cost until it is sold, which can help to reduce their taxable income.

FIFO is generally the better inventory management technique for most businesses because FIFO is more accurate and easier to implement. FIFO is also more consistent with the way that businesses typically sell or use inventory.

However, there are some cases where LIFO may be a better choice for a business. For example, brands that sell perishable items or items that have a limited shelf life should use FIFO. Businesses that sell items that are not perishable and that do not have a limited shelf life may also want to consider using LIFO, especially if they are concerned about their tax burden or inflation.

Demand Forecasting

Demand forecasting is the process of predicting future demand for products or services. It is an essential part of inventory management, as it helps businesses to ensure that they have the right inventory count on hand to meet customer demand. You can also explore our deep dive in inventory management KPIs to get a better understanding of all the major factors at play in terms of inventory and logistics success.

Demand forecasting is important in inventory management for a number of reasons. Demand forecasting helps businesses to avoid stockouts and unnecessary extra inventory. Demand forecasting also helps businesses to plan their production and purchasing schedules. By knowing how much demand they expect in the future, businesses can plan their production and purchasing schedules accordingly. This can help businesses to reduce dead stock, inventory turnover, and can help improve their overall efficiency.

There are a number of steps that businesses can take to implement demand forecasting.

- Gather data. The first step is to gather historical sales data, market research data, and other relevant inventory data.

- Choose a forecasting method. Once the data has been gathered, the business needs to choose a forecasting method. There are a number of different forecasting methods available, such as time-series analysis, causal analysis, and expert judgment.

- Make forecasts. Once the forecasting method has been chosen, the business can start making forecasts for future demand.

- Monitor and update forecasts. Forecasts should be monitored and updated regularly to ensure that they are accurate.

Minimum Order Quantity (MOQ) vs. Economic Order Quantity (EOQ)

MOQ and EOQ are both important concepts in inventory management. By understanding the differences between MOQ and EOQ, brands can set effective MOQs and EOQs to maintain optimal inventory levels.

Minimum Order Quantity (MOQ) is the smallest amount of inventory that a supplier is willing to sell to a customer. MOQs are typically set by suppliers to reduce their costs and to ensure that they are able to meet the needs of all of their customers.

Economic Order Quantity (EOQ) is the optimal amount of inventory to minimize inventory holding costs and ordering costs. EOQ is calculated using a number of factors, including the cost of inventory, the cost of placing orders, and the demand for the inventory.

The main difference between MOQ and EOQ is that MOQ is set by the supplier, while EOQ is calculated by the buyer. MOQs are typically higher than EOQs because suppliers want to reduce their costs and ensure that they are able to meet the needs of all of their customers.

MOQ and EOQ are both important in maintaining optimal inventory levels. MOQ helps to ensure that businesses have enough inventory to meet customer demand, while EOQ helps to minimize inventory costs.

When setting MOQs, brands should consider the supplier’s MOQ, the business’s negotiation power and the business’s inventory needs. When setting EOQs, brands should consider the cost of inventory, the cost of placing orders, the demand for the inventory and the lead time for the inventory.

ABC Analysis

ABC analysis is an inventory management technique that classifies inventory items into three categories based on their value. A items are the most valuable items in inventory and account for the majority of the business’s revenue; B items are less valuable than A items but still account for a significant portion of the business’s revenue; and C items are the least valuable items in inventory and account for a small portion of the business’s revenue.

ABC analysis is based on the Pareto Principle, which states that 80% of the effects come from 20% of the causes. In the context of managing inventory, this means that 80% of a business’s revenue typically comes from 20% of its inventory items.

ABC analysis helps businesses to focus their inventory management efforts on the most important items in inventory. This can lead to a number of benefits, such as reduced inventory costs, improved customer service, and increased sales. By focusing on A items, brands can reduce their inventory costs by avoiding overstocking of less important items and improve customer service by avoiding stockouts.

To perform ABC analysis, businesses need to follow these steps:

- Identify the value of each inventory item by calculating the annual revenue generated by each item.

- Calculate the cumulative percentage of the total value for each inventory item by sorting the inventory items in descending order by value and then calculating the cumulative percentage of the total value for each item.

- Classify the inventory items into A, B, and C categories. A items are typically classified as the top 20% of inventory items by value, B items are typically classified as the next 30% of inventory items by value, and C items are typically classified as the bottom 50% of inventory items by value.

Safety Stock Inventory

Safety stock is an extra quantity of inventory that a business keeps on hand to protect against unexpected events, such as supply chain disruptions, changes in customer demand, or production delays. Safety stock is especially important for businesses that sell essential products or that have long lead times for their raw materials.

Stockouts can have a number of negative consequences for businesses, including lost sales, dissatisfied customers, and damage to reputation. Safety stock can help businesses to prevent stockouts by providing a buffer against unexpected events.

There are a number of different ways to calculate safety stock. One common method is to use the following formula:

- Safety Stock = Maximum Daily Usage * Maximum Lead Time * Service Level

Maximum Daily Usage is the highest number of units of a product that a business is likely to use in a single day. Maximum Lead Time is the longest amount of time that it takes to receive a shipment of a product from a supplier. Service Level is the desired percentage of customer orders that a business wants to be able to fulfill without a stockout.

Just-in-Time Inventory Management

Regarding how to keep track of inventory, just-in-time (JIT) inventory management is a strategy in which businesses receive goods as close as possible to when they are actually needed for production or to meet customer demand. The goal is to eliminate waste and increase the efficiency of operations.

There are a number of benefits to JIT inventory management, including reduced inventory costs, improved efficiency and increased flexibility.

JIT is different from traditional inventory management in that the traditional inventory management method focuses on keeping a large buffer of physical inventory on hand to avoid stockouts. JIT, on the other hand, focuses on reducing inventory levels to the minimum necessary.

Here are a few steps that businesses can take to implement JIT inventory management:

- Identify the products that are most suitable for JIT. JIT is not suitable for all products. Businesses should identify the products that are most suitable for JIT based on factors such as demand predictability, lead times, and cost.

- Develop close relationships with suppliers. JIT businesses need to have close relationships with their suppliers to ensure that they can receive goods on time and in the quantities that they need.

- Implement a robust inventory management system. A robust inventory management system is essential for JIT businesses to track inventory levels and identify potential stockouts.

- Train employees on JIT principles and procedures. All employees involved in the inventory management process should be trained on JIT principles and procedures.

Lean Manufacturing System

The lean manufacturing system is a production method aimed primarily at reducing waste within a manufacturing operation. It was developed by Toyota in the 1950s and 1960s, and it has since been adopted by businesses of all sizes and industries around the world.

The lean manufacturing system is based on the following principles:

- Identify and eliminate waste/inventory turnover

- Make products only when and where they are needed

- Create continuous flow

- Empower employees

The lean manufacturing system minimizes waste by focusing on reducing inventory levels, improving efficiency, and empowering employees. Inventory is waste because it ties up cash, takes up space, and can become obsolete. Lean manufacturing techniques such as just-in-time inventory management and Kanban can help to improve efficiency and reduce waste. By empowering employees to identify and solve problems on their own, lean manufacturing helps to reduce waste caused by errors and inefficiencies.

There are a number of ways to implement lean manufacturing in inventory management. Some common techniques include:

- Just-in-time inventory management. Just-in-time inventory management, as mentioned, is a strategy in which businesses receive goods only as they need them for production or to meet customer demand. This helps to reduce inventory levels and waste.

- Kanban. Kanban is a visual system for managing inventory and workflow. It helps to ensure that materials are moved through the production process in a timely and efficient manner.

- 5S. 5S is a workplace organization system that helps to create a clean, organized, and efficient work environment. This can help to reduce waste and improve efficiency.

Batch Tracking

Batch tracking is a process of tracking and managing products or items in groups based on their production date, lot number, or other shared characteristics. This allows businesses to track the movement of products through the supply chain and to identify and recall specific batches of products if necessary.

Batch tracking is a supply chain management strategy commonly used in the food and beverage industry, but it can also be used in other industries such as pharmaceuticals, cosmetics, and electronics. Learn how Flowspace’s food and beverage fulfillment solutions can help your business today.

Batch tracking allows businesses to track the movement of products through the supply chain from raw materials to finished goods. This helps brands to identify and resolve any quality or safety issues that may arise.

If a problem is identified with a particular batch of products, batch tracking allows brands to quickly and efficiently recall those products. This helps to reduce the risk of customers being exposed to unsafe products and can minimize the damage to the business’s reputation.

There are a number of different ways to implement batch tracking. One common method is to use barcodes or QR codes to identify each batch of products. The barcodes or QR codes can then be scanned at various points in the supply chain to track the movement of the products.

Another method for batch tracking is to use a batch tracking software system. Batch tracking software systems can help businesses to track the movement of products through the supply chain, manage inventory levels, and identify and recall specific batches of products if necessary.

Six Sigma in Inventory Management

Six Sigma is a data-driven quality improvement methodology that helps businesses to reduce defects and improve efficiency. Six Sigma is based on the concept that by identifying and eliminating the root causes of defects, businesses can significantly improve their performance.

Six Sigma uses a five-step process called DMAIC, which stands for Define, Measure, Analyze, Improve, and Control. The DMAIC process is used to identify and eliminate the root causes of defects and to develop and implement solutions.

Six Sigma can be used to reduce defects and waste in inventory management in a number of ways. For example, Six Sigma can be used to reduce the number of stockouts, reduce excess inventory, improve inventory accuracy, reduce inventory shrinkage, and improve inventory forecasting.

There are a number of different ways to implement Six Sigma. One common approach is to use the DMAIC (Define, Measure, Analyze, Improve, Control) methodology.

- Define: Clearly articulate the problem, scope, and desired outcomes.

- Measure: Collect data on the current state of the process.

- Analyze: Identify the root causes of the problem.

- Improve: Implement solutions to address the root causes.

- Control: Monitor the process to ensure improvements are sustained.

Consignment Inventory

Consignment inventory is a type of inventory arrangement in which the owner of the goods (the consignor) gives the goods to another party (the consignee) to sell for them. The consignee only pays the consignor for the goods that they are able to sell. This type of inventory arrangement is common in retail, where stores may sell products on consignment from suppliers.

For the consignor, consignment inventory can be a way to reach new customers and increase sales without having to invest in their own retail space or sales staff. For the consignee, consignment inventory can be a way to offer a wider variety of products to their customers without having to invest in inventory upfront.

For the consignor, consignment inventory can be risky because they do not get paid until the goods are sold. For the consignee, consignment inventory can be more time-consuming to manage than traditional inventory because they must track the sales of each consigned item and remit payment to the consignor.

Consignment inventory can be a good option for businesses in a number of situations, including:

- When a business is new and does not have the resources to invest in a large inventory upfront.

- When a business wants to offer a wider variety of products to its customers but does not have the space or resources to carry all of the products in-house.

- When a business is selling seasonal products or products with a short shelf life.

Perpetual Inventory Management

Perpetual inventory is a method of inventory management that tracks inventory levels in real time. This is done by recording every transaction that affects inventory levels, such as purchases, sales, and returns. Perpetual inventory systems can be manual or computerized.

Perpetual inventory systems continuously track inventory, unlike periodic systems which only count inventory at specific times of the year. By allowing businesses to identify low inventory levels in real time, perpetual inventory systems prevent stockouts and ensure customer satisfaction. Additionally, these systems help businesses reduce costs by identifying and eliminating excess inventory. With perpetual inventory systems, businesses can maintain optimal inventory levels, meet customer demands, and increase efficiency.

There are a number of ways to implement perpetual inventory management. One common approach is to use a barcoding system. Barcodes can be used to track the movement of inventory throughout the supply chain, from the warehouse to the store shelf.

Another approach to implementing perpetual inventory management is to use a radio frequency identification (RFID) system. RFID tags can be attached to individual inventory items and used to track their movement in real time.

Once a system for tracking inventory transactions has been implemented, businesses need to develop procedures for updating their inventory records in real time. This may involve training employees on how to use the system and developing new procedures for processing inventory transactions.

How Flowspace Can Help

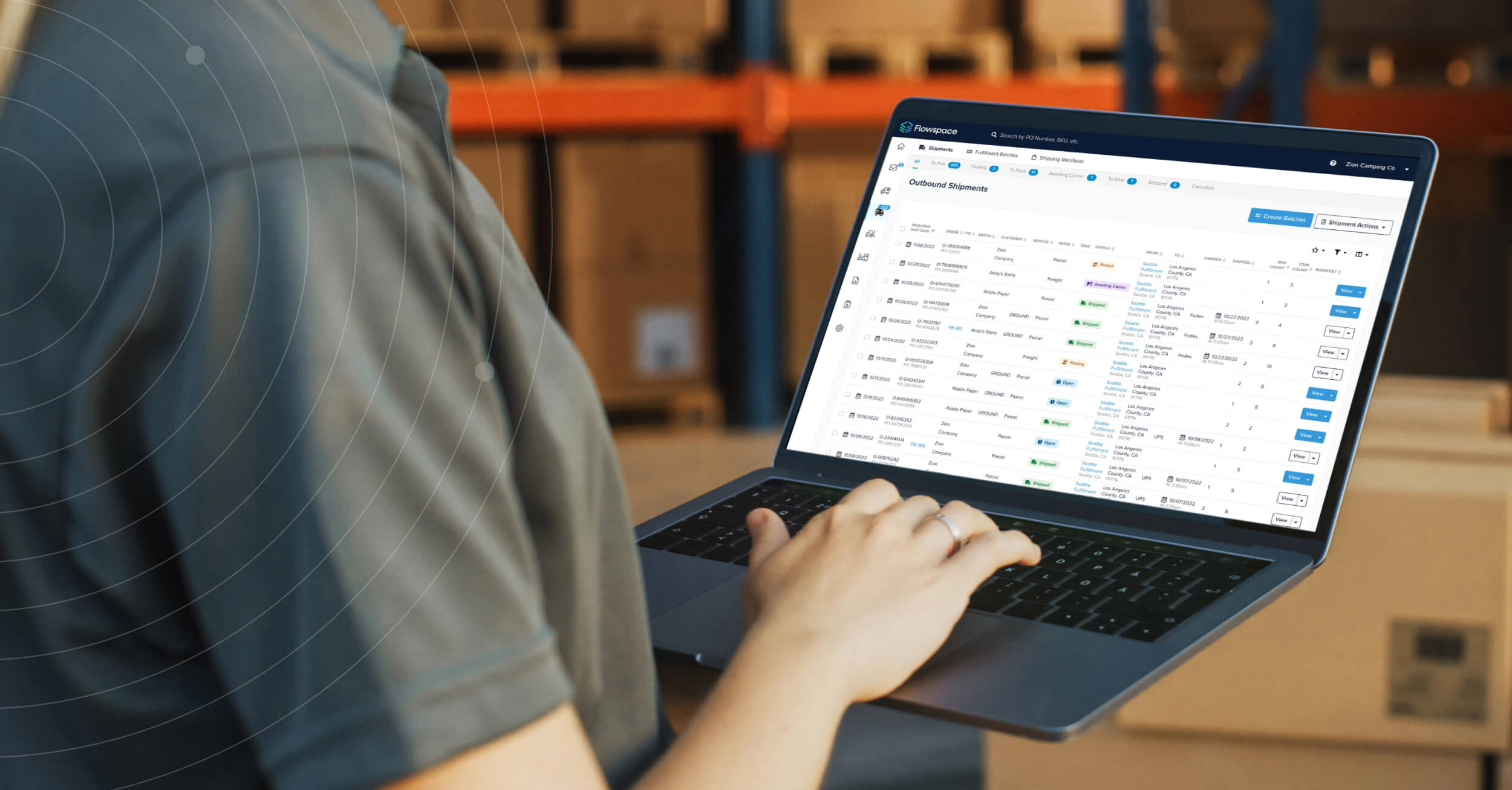

With Flowspace, brands can seamlessly connect their DTC and B2B sales channels in one platform, allowing them to manage their inventory and customer orders from one convenient central location. Flowspace integrates smoothly with popular ecommerce platforms like Shopify, Magento, and WooCommerce, and offers retail-compliant EDI compatibility, ensuring a seamless flow of information regardless of where a brand’s sales are coming from.

One of the key features of Flowspace’s platform is real-time inventory tracking with our real-time inventory management software. By providing instant visibility into stock levels and location, brands can avoid stockouts and ensure prompt and accurate fulfillment of orders. Plus, the platform sends alerts when inventory levels are low, empowering brands to reorder products before they run out.

Flowspace’s platform also leverages historical sales data and other factors to help forecast future product needs. This means brands can avoid overstocking, saving them money on unnecessary inventory costs. Whether a brand is just starting out or already a large enterprise, Flowspace’s platform is designed to scale according to their business needs.

Discover how Flowspace’s order fulfillment software can optimize your inventory management. Contact us today to learn more!