Long gone are the days of paper invoices and disparate spreadsheets housing customer data. Today’s savvy brands are all in on supply chain digitization and are reaping the benefits that these digital tools offer.

Supply chain digitization and fulfillment technology can have a profound impact on a brand’s bottom line by making everything—including supply chain operations and fulfillment—more efficient. Read more about supply chain digitization and its benefits for your brand.

What Is Supply Chain Digitization?

Supply chain digitization is the process of replacing outdated manual or analog processes with new high tech solutions centered around digital transformation. Software allows brands to aggregate data into one solution that focuses on automation and business intelligence.

While most supply chains use technology or advanced analytics in some way, the big difference in a digitized supply chain is that the technology systems are integrated, which reduces silos and allows them to work seamlessly together.

This digital technology software can be an out-of-the-box solution, a custom-made one, or even a combination of both. There have never been more options for digital supply chain operations than there are now, which means it’s easier than ever for brands to find a solution that works for their specific needs.

What Are the Benefits of Supply Chain Digitization?

Digitizing an entire flexible supply chain strategy has benefits that can extend to every part of a brand’s operations.

Improve Financial Management

Having real-time visibility into supply chain logistics like inventory is one of the benefits of supply chain digitization and allows brands to better manage financials. Being able to see inventory levels in real-time can ensure the optimal stock level to meet surges in consumer demand without wasting resources on excess inventory.

The line between stockouts and overflow can be thin, and investing in an inventory tracking system ensures that every product in every warehouse (if you’re using more than one fulfillment center) is accounted for. This makes sure products don’t get overlooked and stuck on warehouse shelves—which can negatively impact the bottom line.

Minimize Lead Times

Digitizing a supply chain offers improved analytics and tracking at all levels of the business, which can help minimize lead times for orders. For example, integrating ecommerce software with order fulfillment software means that as soon as orders come in, they are ready for fulfillment.

Eliminating manual work and speeding up processes between departments is so important as customers increasingly expect fast turnaround times. This makes supply chain digitization a critical part of improving a brand’s supply chain efficiency.

Increase Automation

A connected and digitized supply chain process reduces the need for manual work, which can free up employees’ time for other tasks. Automation also reduces the potential for human error. Digital supply chain management can integrate disparate systems and departments and creates a one-stop-shop for critical data.

Improve Decision-Making with Real-Time Customer and Business Analytics

Having access to real-time data on inventory and consumer behavior can give brands an edge in planning ahead and not getting caught behind the curve.

For example, looking for seasonal trends can ensure beauty brands stock up on products with SPF before demand starts to pick up in the spring. While that trend might seem obvious, predictive analytics might also help brands detect a smaller demand increase around the end of the year when people might be taking tropical vacations.

How to Implement a Digitized Supply Chain Strategy

Digitization has become a requirement for modern brands, and there are two options for supply chain digitization: building in-house or partnering with a third-party logistics company.

Building a system in-house ensures a completely unique digital supply chain solution that can meet a brand’s specific needs, but that comes at a cost—both financially and time-wise. This approach requires developing a system from scratch that either replaces or integrates with systems that a brand already uses.

Partnering with a company that offers a supply chain planning solution means purchasing a system that has been proven successful. Many companies offer out-of-the-box software that can digitize the supply chain process and allow brands to take advantage of all of the benefits.

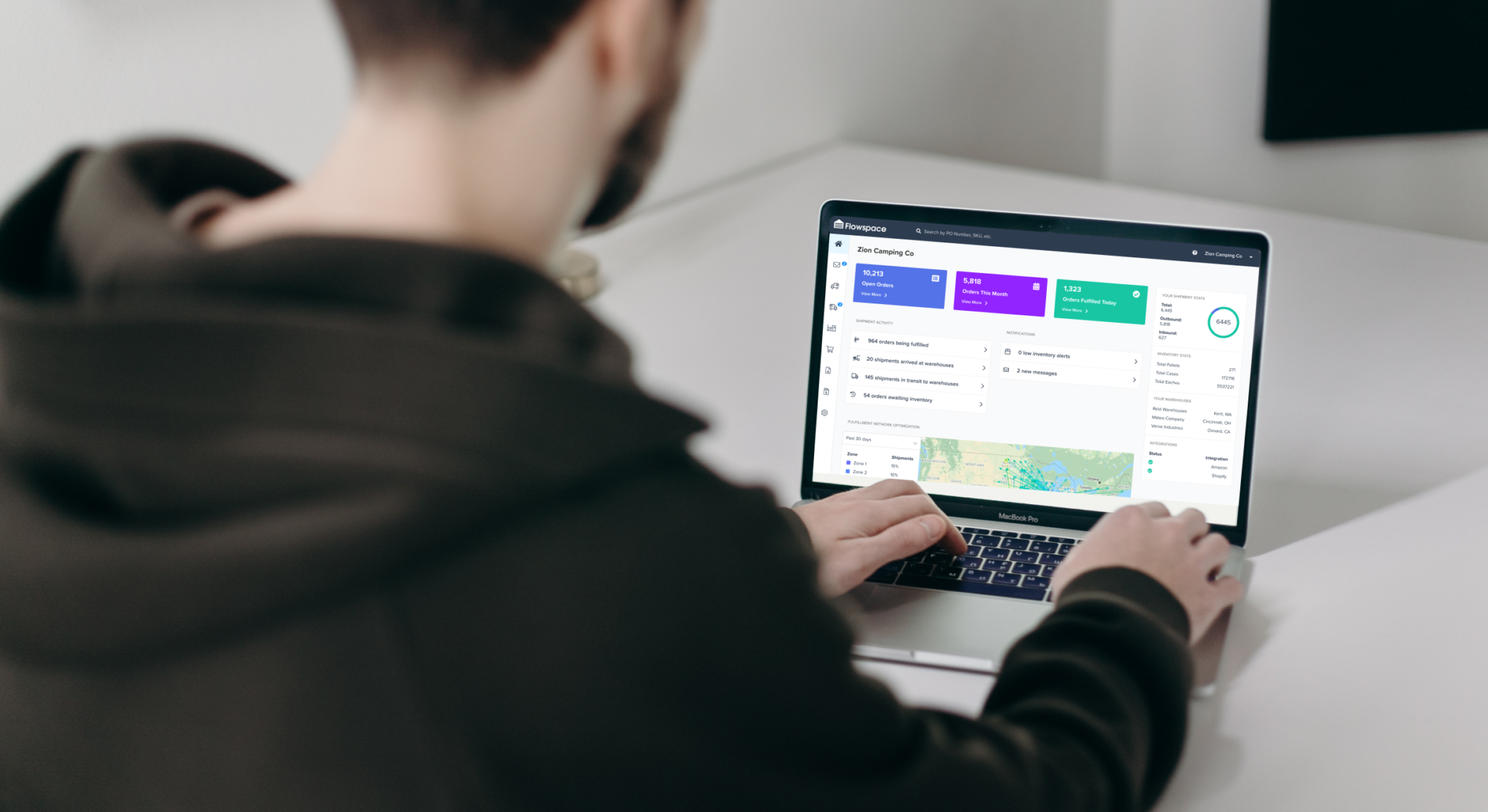

Flowspace offers an industry-leading software that powers insights and efficiencies for brands selling online and in retail. Flowspace’s solution offers a suite of digital tools purpose-built for the modern commerce brand, including real-time visibility, inventory management, order management, and network optimization.

Flowspace makes production inventory management easy by providing complete inventory visibility of inbound logistics, outbound logistics, and in-progress stock. Ensure an optimal stock level with real-time inventory tracking, low inventory level alerts, and a predictive view of remaining products. With accurate customer analytics like demand insight, you can better manage inventory by having safety stock to avoid low inventory count situations while also avoiding excess inventory costs.

Brands need to make sure they aren’t left behind and can take advantage of all of the benefits supply chain digitization has to offer and can thrive for years to come. Partnering with a 3PL like Flowspace can help brands reach that next level.

Have other fulfillment-related questions? Whether you are interested in learning about strategies to help you prepare for what may arise in your company’s day-to-day supply chain operations, want to learn how to optimize your company’s return process, or need clarification on what is inventory control, we have you covered at Flowspace. Get in touch today.